19

2025

-

04

Citric acid monohydrate crystallization tank introduction

1. Structure

Citric acid monohydrate crystallization tank is a device for crystallization of citric acid solution, mainly composed of the following parts:

Tank: Used to hold citric acid solution, usually made of a corrosion-resistant material, such as stainless steel or fiberglass.

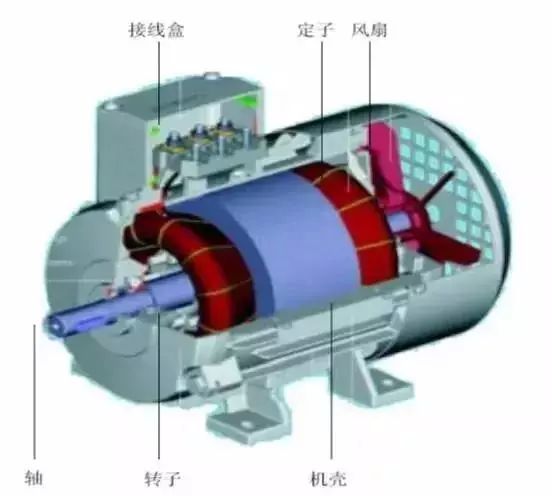

Stirring device: used to evenly mix the solution,which shall ensure the stability of the crystallization process.

Cooling system: Control the temperature of the solution through the cooling medium (such as cold water), which shall promote the process of crystallization.

Feed port and discharge port: for solution inlet and outlet and crystal discharge.

Temperature and pressure sensor: real-time monitoring of the temperature and pressure in the tank, which shall ensure the stability of crystallization conditions.

2. Working principle

The working principle of the citric acid monohydrate crystallization tank is based on the supersaturated state of the solution and the cooling crystallization:

Solution concentration: the citric acid solution is concentrated by heating to a supersaturated state, usually reaching a concentration of 68.5% to 78%.

Cooling crystallization: the solution is cooled in the tank through the cooling system, forming a supersaturated solution, and the crystal is gradually precipitated. During the cooling process, the temperature difference between the cooling medium and the solution is controlled to be no more than 10 ° C to avoid local cooling too fast leading to the generation of secondary crystal nuclei.

3. Crystal growth: by stirring and temperature control, the crystal gradually grows in the tank and it shall reach the required particle size.

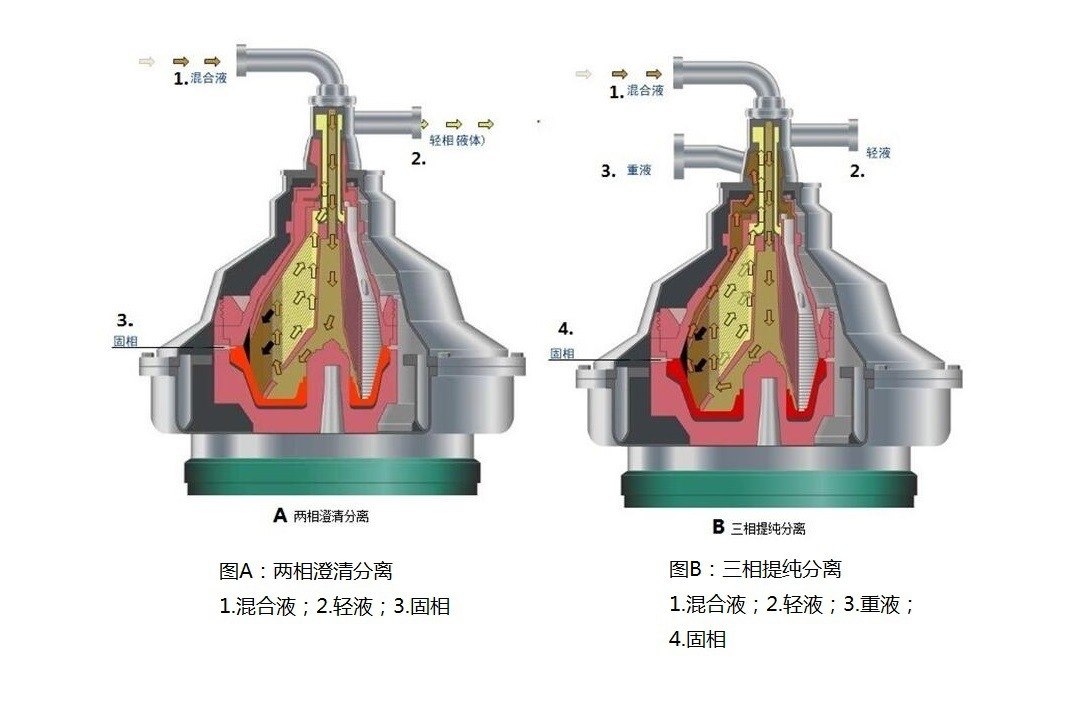

4. Solid-liquid separation: After crystallization is completed, the crystal is separated from the solution through the solid-liquid separation equipment (such as centrifuge) and it shall obtain citric acid monohydrate crystals.

3. Characteristics

Efficient crystallization: By controlling the cooling rate and solution concentration, the uniformity and quality of the crystal shall be improved.

Compact structure: reasonable design, small footprint, easy to install and maintain.

High degree of automation: equipped with temperature, pressure and other sensors, automatic control shall be achieved to ensure the stability of the crystallization process.

Energy saving: Reduce energy consumption and increase production efficiency by optimizing cooling and concentration processes.

Related News

Release time: 2025-04-27

Release time: 2025-04-24

Release time: 2025-04-16

Tel: +86-18663389867

E-mail: dqm@acme-china.com

Address: Room 8006, Excellence Financial Plaza, 215 Shuangzhu Road, Huangdao District, Qingdao, Shandong

Copyright © 2025 ACME Biotechnology CO.,LTD | SEO | Business license