ACME BIO Engineering is your trusted partner!

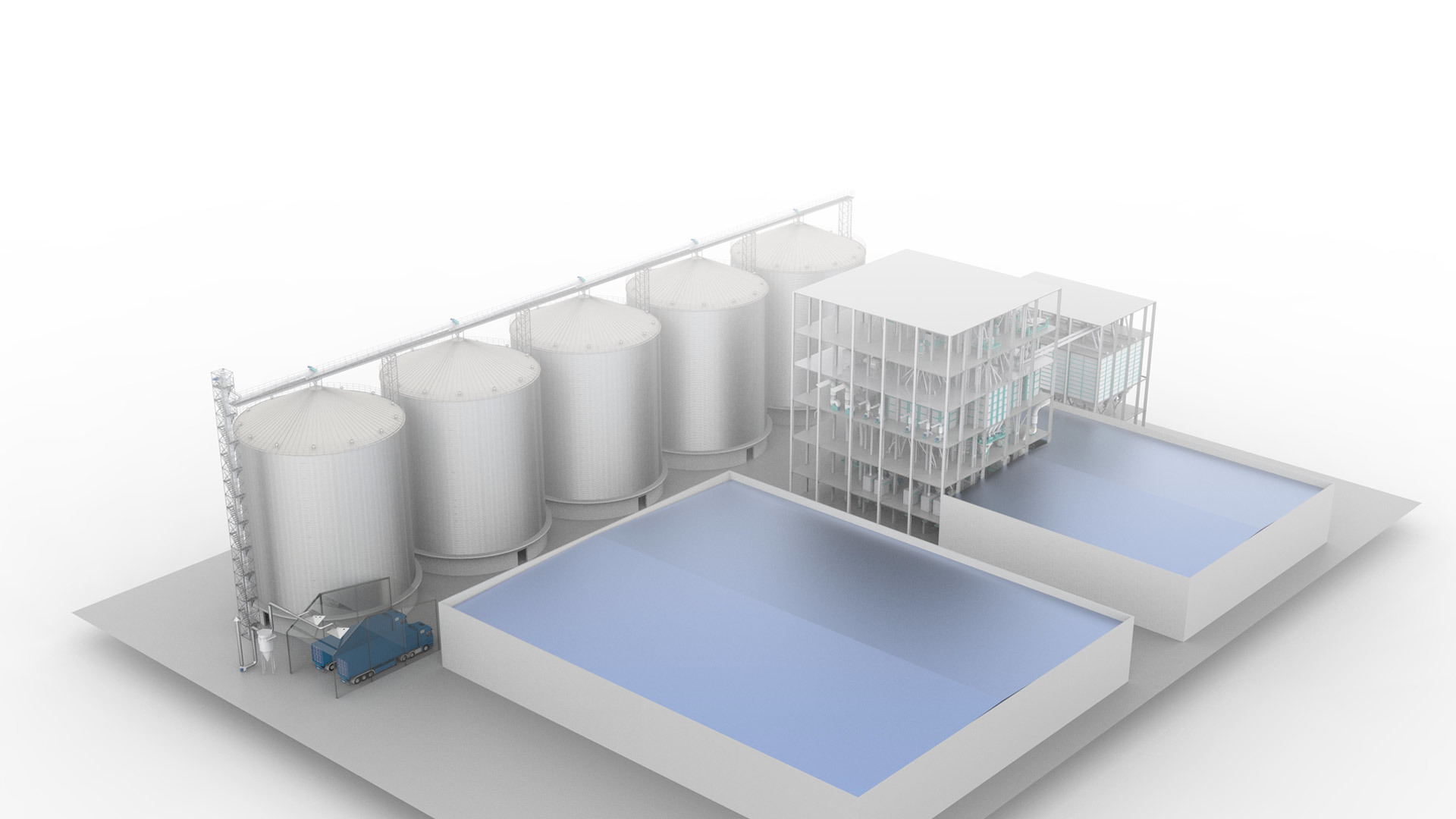

If you are in need, we can not only provide you with a complete design, but also provide proprietary equipment and professional on-site services, leaving you with a complete factory.

ACME is a long-term partner that you can trust!

ACME Biotechnology CO.,LTD

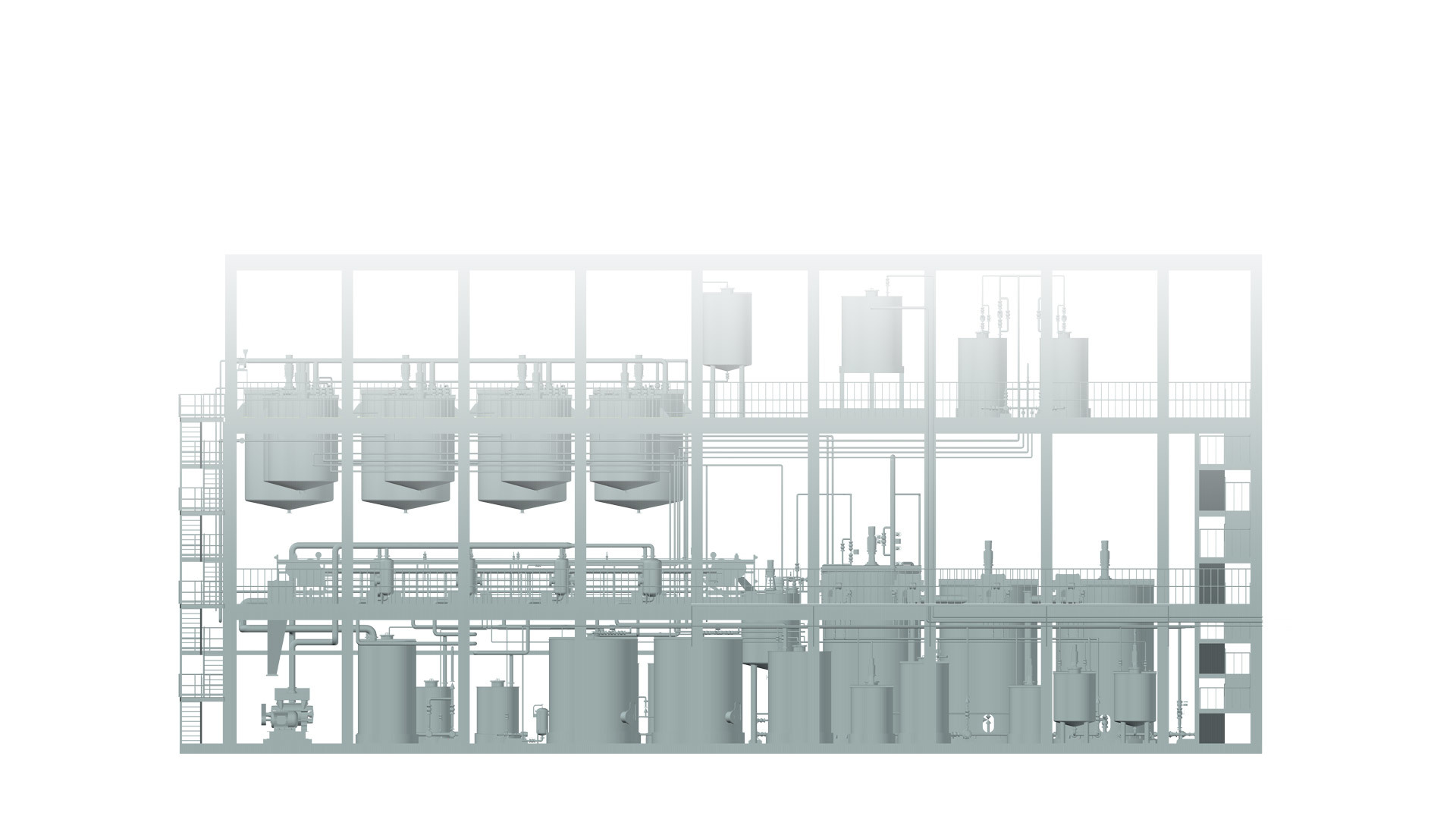

Shandong Acme Biotechnology Co., Ltd(hereinafter referred to as ACME) is mainly engaged in R&D, design and complete sets of technology transfer of corn, wheat,rice and cassava processing technology in terms of starch project, wheat gluten processing,citric acid, lactic acid, amino acid, Xanthan gum,succinic acid, itaconic acid, erythritol and sodium gluconate fermentation engineering, we also provide reoptimization and upgrading of biological fermentation engineering and training on production process management, and carry out production trusteeship business.

ACME provides "one-stop" service covering all aspects of initial study and feasibility assessment, overall design, process design, equipment selection, on-site installation guidance, personnel training, commissioning, start up of the project, and assist the owner to establish and improve the production management system, quality management system and cost management system after the project is put into operation.

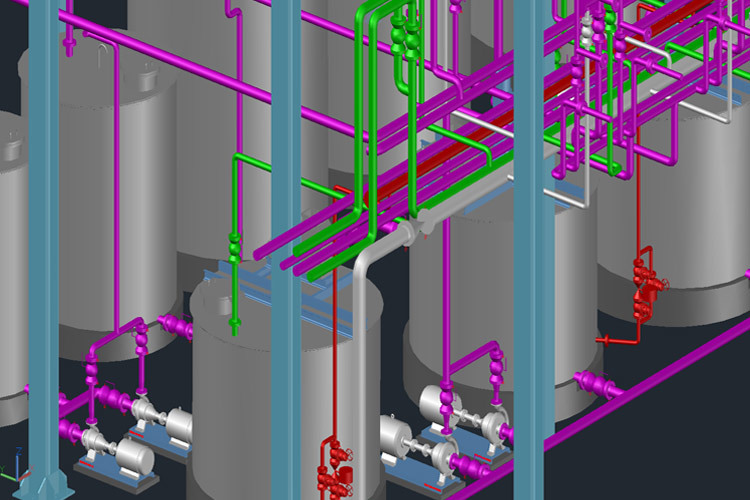

The team members of ACME are experienced in the design, construction and production management of biological fermentation factories with many years of working on strain, fermentation, purification, evaporation, crystalization and relative processes at home and abroad, to ensure the project success.

As a dedicated bioengineering company, ACME knows that product cost, quality, pollution prevention and control are the key factors on the survival and development of enterprises. In this respect, we make comprehensive use of water, electricity and steam in the whole process of production, integrate new energy-saving technology, optimize the process, and achieve water saving, electricity saving, steam saving, and improve product yield. In terms of pollution prevention and control, ACME maintains cooperation with environmental protection engineering companies in the industry, and chooses the best plan to ensure the most cost-effective and effective comprehensive treatment of waste water, waste gas and solid waste in the process, so as to fully present a low consumption, high quality, environmental protection and healthy green factory for our customers and society.

In the spirit of being responsible for customers, we are operation-driven and focus on safety, cost and quality to ensure the success of one-time startup of the project and achieve rapid production capacity and efficiency.

How can we help you?

Tel: +86-18663389867

E-mail: dqm@acme-china.com

Address: Room 8006, Excellence Financial Plaza, 215 Shuangzhu Road, Huangdao District, Qingdao, Shandong

Copyright © 2025 ACME Biotechnology CO.,LTD | SEO | Business license